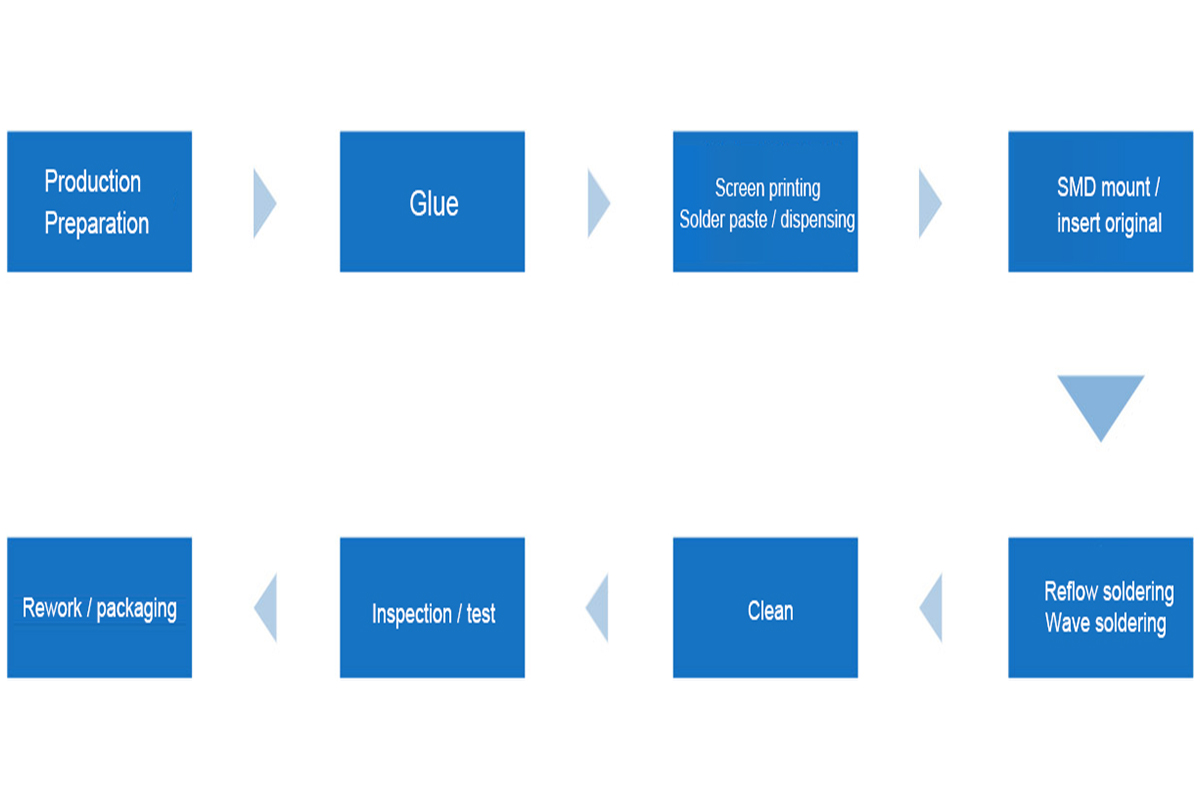

Surface Mount Technology is the most popular technology and process in the electronic assembly industry. It has promoted the miniaturization and multi-functional of electronic products. And it provided the conditions for high-volume, low-defect production rate. At the same time, the widespread use of SMT has also made itself become a huge industry.

Laser technology is widely used in SMT industry, it covering the template cutting, welding, sub-board, marking, cutting, drilling, FPC cutting, cover film and other sub-areas. For example, in the SMT template manufacturing, laser processing instead of the original chemical etching method, precision metal parts laser molding, HDI (high density interconnect technology) laser drilling and so on. It is precisely because of the application of laser technology, so that it has made a new breakthrough in processing.

- For precision and complex structured products, as well as design changes, a small number of research and development samples. Laser can be used directly to production, eliminating the need for the use of a mold (mold production cycle, high costs).