Battery as a core component of new energy vehicles, its quality directly determines the vehicle performance. In the lithium industry, lithium battery manufacturing equipment is generally divided into front-end equipment, midrange equipment, back-end equipment. Its equipment accuracy and automation level will directly affect the product’s production efficiency and consistency.

Laser machines help alternative energy vehicle manufacturers improve quality and efficiency – Laser technology is now widely used in the cutting and welding process of power lithium batteries due to its advantages of high energy density, fast welding speed, high processing accuracy, small heat-affected zones and high safety, which can reduce porosity, cracks and pollution and improve processing efficiency.

The laser processing technology is playing an increasingly important role with its own technological advantages in the lithium battery industry, batteries and modules laser welding, pole piece material cutting, marking, etc. Contact KBF Laser to learn more.

- Laser Welding Technology

From the manufacture of lithium batteries to the battery PACK group, welding is a very important process, lithium battery’s electrical conductivity, strength, tightness, fatigue and corrosion resistance, which is a typical battery welding quality evaluation standard. The selection of welding methods and welding procedures will directly affect the cost, quality, safety and battery consistency of the battery.

- Among many welding methods, laser welding has the following advantages:

Laser welding has high energy density, small welding deformation, small heat affected zone, it can effectively improve accuracy and smooth welding without impurities, uniform and compact without additional grinding work. - Laser welding can control precisely, small focus spots, high precision positioning, with mechanical arm that is easy to realize automation, improving welding efficiency, reducing working hours, reducing the cost.

- while laser weld the thin plate or small diameter wire, it isn’t like arc welding which is susceptible to melt back problems.

The structure of the battery usually contains a variety of materials, such as steel, aluminum, copper, nickel and other metals, these may be made of electrodes, wires, or shell. Therefore, whether it is one material welding or welding between various materials, all that are put forward higher requirements on the welding process. The advantage of laser welding lies in the wide range of welding materials and can realize the welding between different materials.

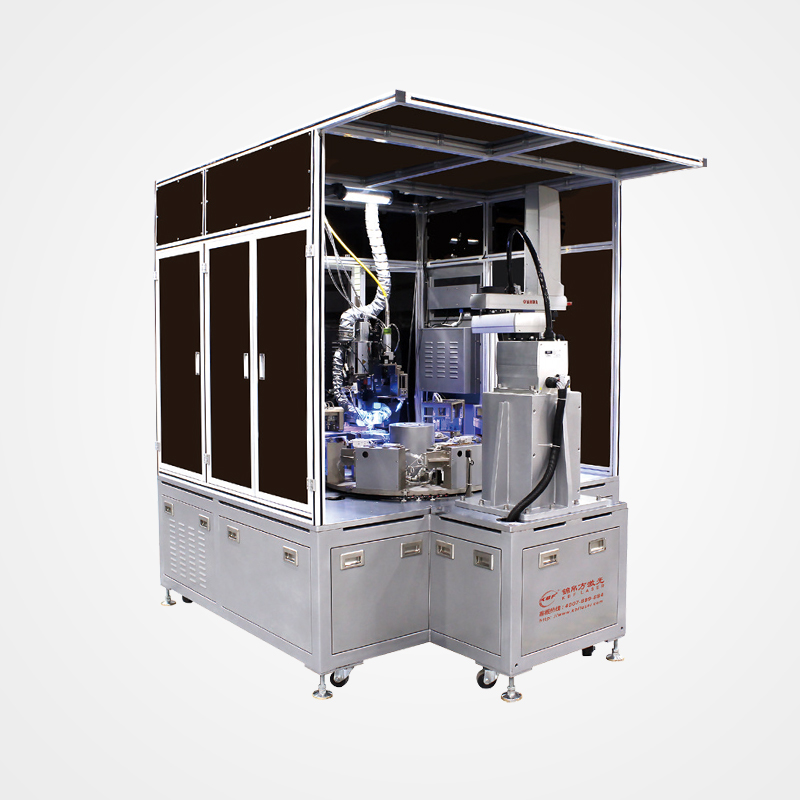

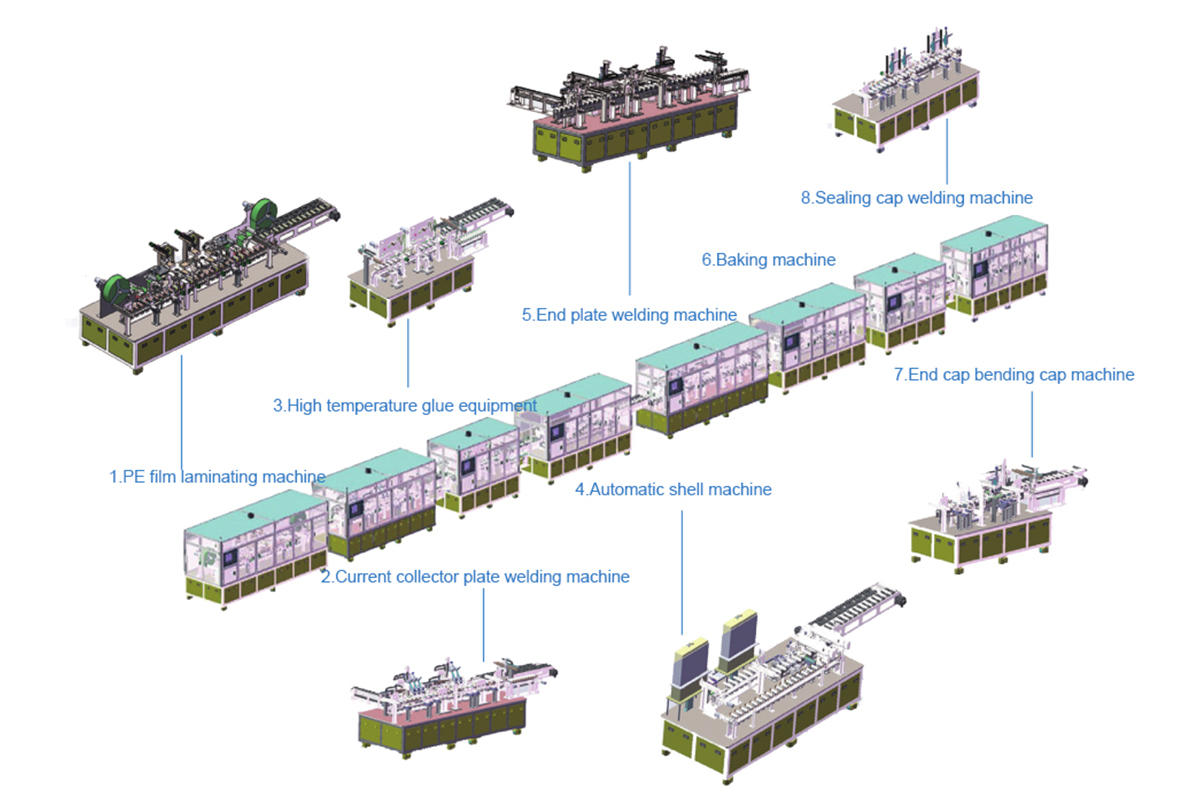

With many years of experience in laser process applications, KBF has combined laser welding technology with automation and intelligent systems in power battery manufacturing to create a complete set of laser processing solutions and related supporting facilities. Our battery laser welding machines plays an important role in EV manufacturing.

- Battery Tab Cutting

Laser welding is widely used in the manufacture of lithium batteries, and almost runs through all aspects of production. The production of lithium batteries, especially power lithium batteries, requires cutting lug, but the traditional die-cutting method is not only costly, but also prone to safety problems. Die cutter in the process of use, will inevitably appear wear and tear, and then drop dust, burr. And dust, burr is the cause of battery overheating, short-circuit, explosion and other dangerous issues culprit. To avoid danger, die-cutting knives need to be replaced frequently. But its price is as high as hundreds of thousands of yuan, or even millions of yuan, so a die-cutting machine costs millions of dollars a year. A lithium battery production line is often equipped with 8~10 die-cutting machines, which leads to the cost of material consumption of the die-cutting machine in the entire lithium battery production costs accounted for a large proportion.

Compared with the traditional cutting mode, laser cutting is an online with high power cutting mode,one is no supplies, greatly reducing the cost; the two is fast and can greatly improve the production efficiency; three is high flexibility, not only can make the cutting process design and test of new products from the past several months to a few days,and spacing, size etc. can also become free control. In terms of cost, a one-time increase of only 30%, very short time will be able to recover costs. vantages such as no wear, flexibility, high precision and no contact. This makes the KBF high precision laser cutting machines ideal for the processing of lithium batteries.