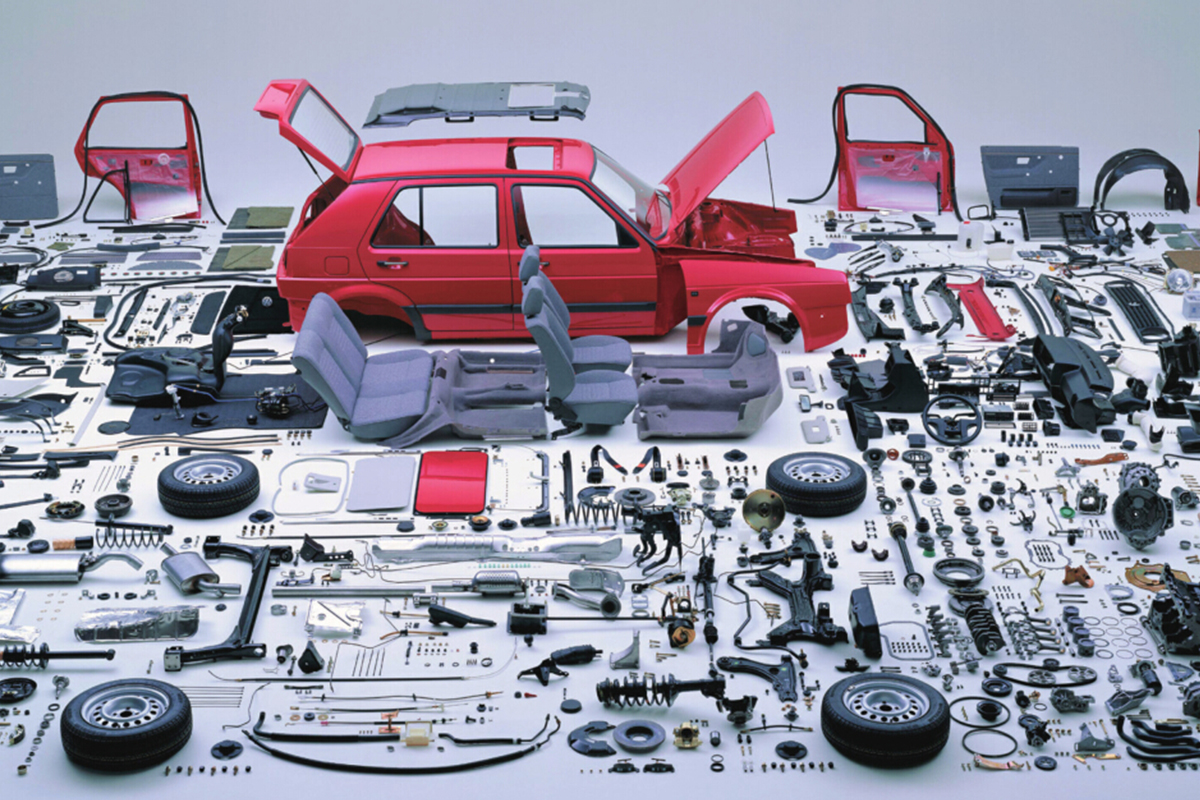

Laser welding has become one of the important means in automobile manufacturing because of its high energy density, small deformation, narrow heat affected zone, high welding speed, easy to realize automatic control and no follow-up processing. There are hundreds of thousands of parts in a car body and chassis. It has a direct impact on the vehicle body how to connect them together. The use of laser welding can almost connect all the different thickness, grade, type and grade of metal materials together, creating strong and precise welds.. In the promotion of production efficiency and quality at the same time also increased the automotive design and flexibility of material selection. This is particularly useful in the production of auto parts, such as engine components, transmission parts, and chassis components.

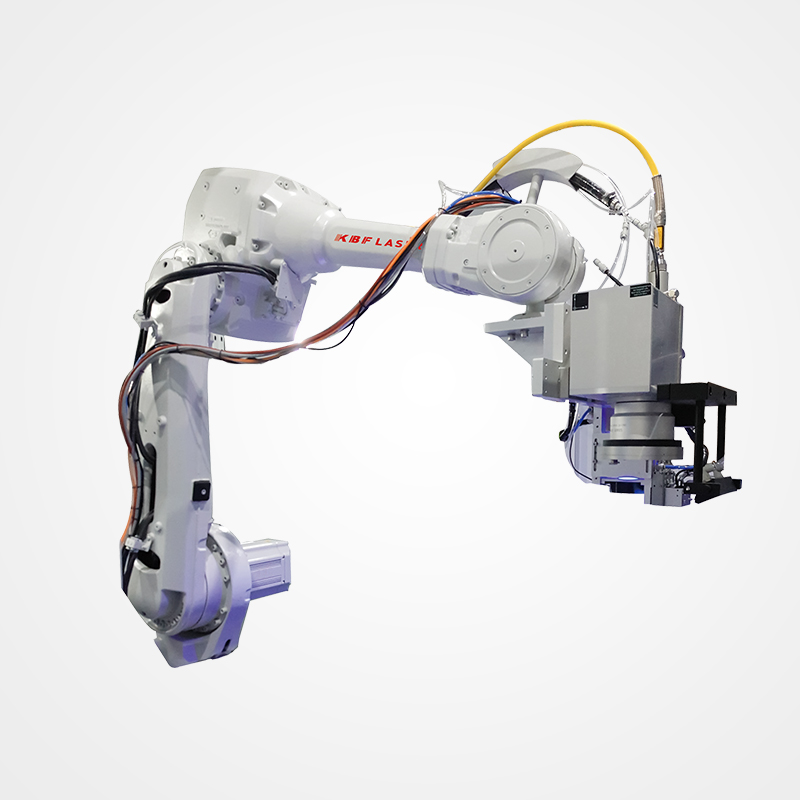

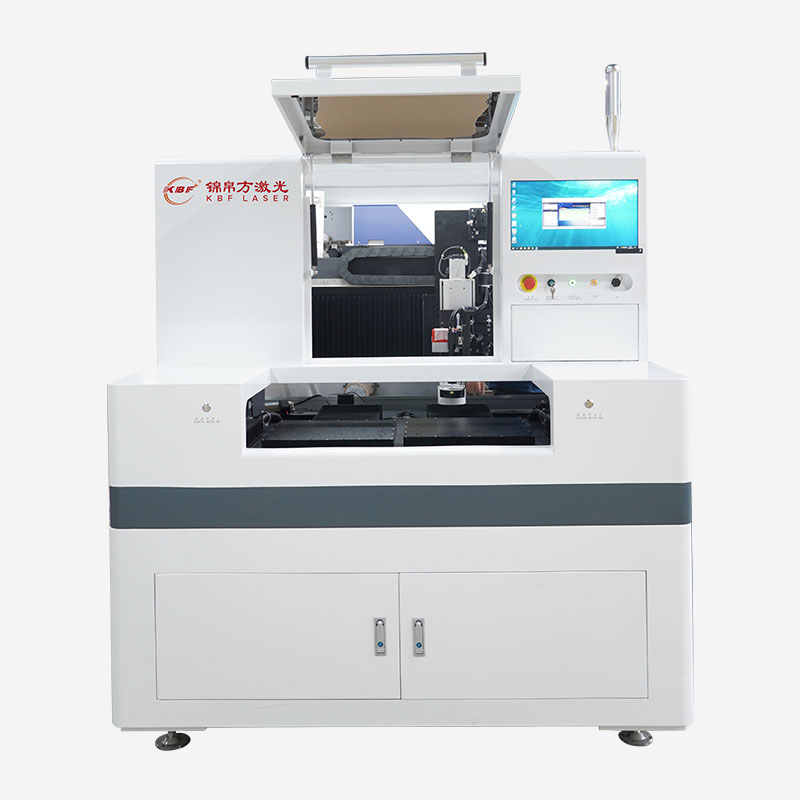

Laser cutting is one of the most commonly used laser processing methods, laser cutting type is divided into laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and control fracture four categories. Compared with the traditional processing methods, laser cutting has a higher cutting quality – narrow incision width, small heat affected area, smooth incision, cutting speed, flexible – free to cut any shape, a wide range of material adaptability and so on. It is often necessary for three-dimensional laser cutting machines to cut off the large parts of a car. In addition, the current automotive manufacturing platform intensified, the flexibility of the production line put forward a higher demand. Using three-dimensional laser cutting in the model of the model changes, just need to adapt laser processing procedures. And tooling is simple, greatly shorten the duration, relative to the use of mold manufacturing costs dropped significantly. In addition, the application of high-strength steel in automotive manufacturing improved, and the stamping process is no longer appropriate for this steel after thermoforming. The cutting of contours and holes has pushed the demand for laser cutting.

In the production of automobiles and parts, the establishment of identity is the basis of quality retrospect and recall. Establishing the uniqueness of identity of automobiles and auto parts by marking is critical. Automobile marking with its high efficiency and adaptability and permanent has been more and more widely used. Laser marking is a kind of mark method that use the high energy density laser to exposure on the workpiece locally, so that the surface material produce the chemical reaction of vaporization or the color changes, then leaving a permanent mark. Laser marking is characterized by non-contact processing, marking in any special-shaped surface, the workpiece will not deform and produce internal stress. Modern automotive parts use a variety of materials, including metal, plastic, glass, ceramics, wood and leather, etc., and the use of laser can do surface marking in all of these materials perfectly.