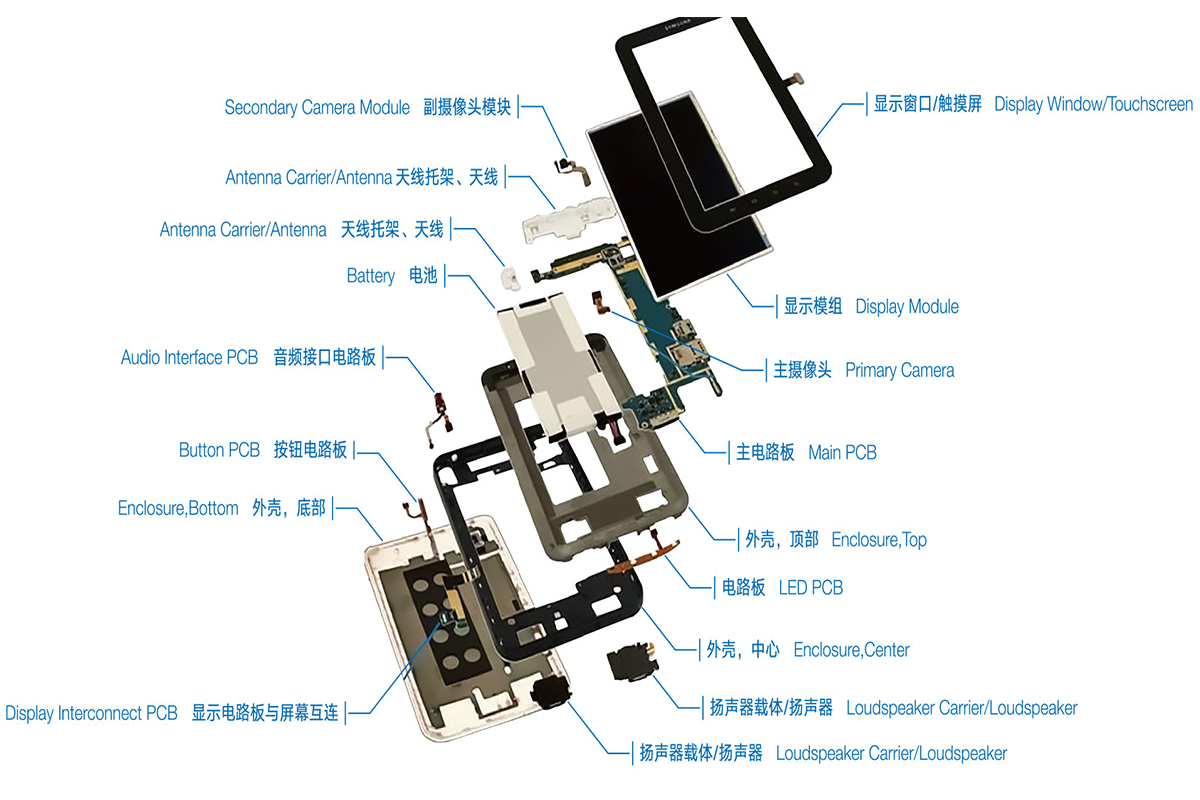

3C industry is the abbreviation of three categories of electronic products: Computer, Communication and Consumer Electronics. With the rapid development of the electronics industry, electronic products upgraded towards the direction of high integration, high precision.

Its product components are getting more and more compact, precision, electronic integration is getting higher and higher. In product development, lighter, thinner, more portable design is the goal of the designer, which brings advances in new materials, new technology, and laser is the representative of rapid development electronic products manufacturing.

Because of the small heat-affected area of laser processing, precision machining, high processing speed, it’s easy to achieve the technology which conventional methods can not be achieved easily, laser marking has been more widely used in the 3C industry.

- Large-scale

- Process Innovation

- Mainstream