As a laser application company integrating R&D, production, and sales, KBF Laser has 65% of technical and R&D personnel. Over the past ten years, we have provided numerous laser solutions for domestic and foreign production lines.

Our OEM laser system allows customizing laser machines according to clients’ needs. We provide a one-stop solution, from system designing to manufacturing.

Lithium battery cells/PACK module solution: battery Tab laser cleaning/cutting/welding, battery PACK automatic production line, 3C and other customized automated laser equipment.

Ultra-fast micro-fine laser processing: cutting, splitting and chamfering of TFT liquid crystal and industrial glass.

SMT online traceability system, LCD cutting system, Precision laser welding system. Contact KBF Laser to learn more.

KBF Laser is a laser cutting machine manufacturer, providing one-stop solutions for various industries: Lithium battery fully automatic processing system Ultra-fast micro-fine laser processing, Battery Tab Laser Cutting System, Lithium battery module PACK assembly production line.

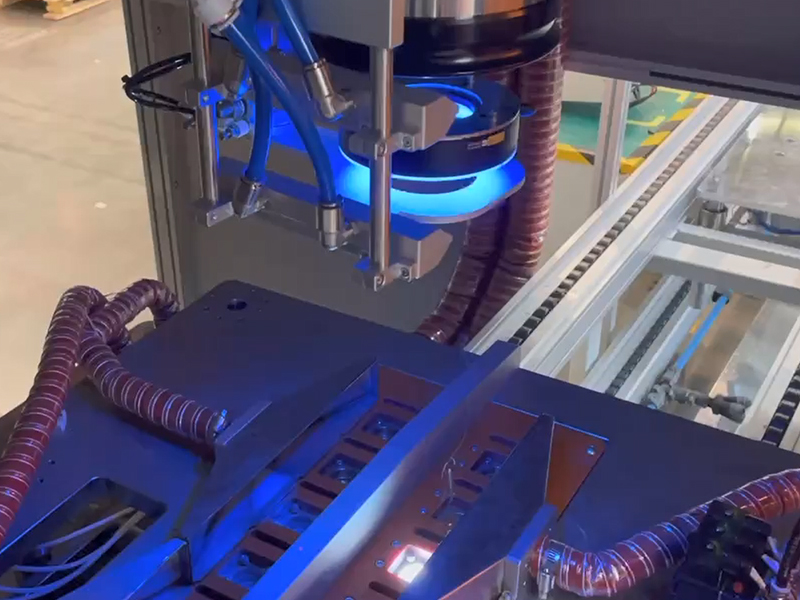

Lithium Battery Fully Auto-processing System

Under the premise of safety production as the primary condition, the system takes the energy feedback charging and discharging equipment as the core, and effectively connects the functional modules through the automatic logistics system, so as to realize the whole automation of the battery post-production processing process.

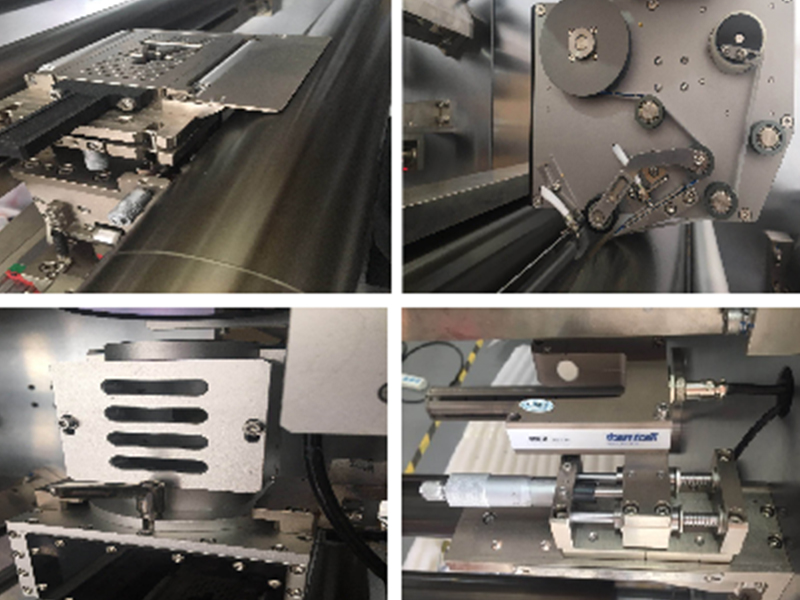

Battery Tab Laser Cutting System

Cutting and forming of tabs of power battery poles: unwinding-single/double cutting-CCD inspection-slitting-rewinding 1.The cutting system is directly connected with the MHI through TCPIP, humanized operation 2.Using PSO technology to ensure the cutting effect 3.Cut the mark hole directly, the position of the mark hole can be adjusted 4.Parallel symmetrical cutting function, no defective products.

Lithium Battery Module PACK Line

Production automation of square aluminum shell modules, and automatic assembly of module PACK.